Summary of Consolidated Financial Results for the Three Months Ended June 30, 2019 (Based on Japanese GAAP)

Summary of Consolidated Financial Results for the Six Months Ended September 30, 2019 (Based on Japanese GAAP)

Summary of Consolidated Financial Results for the Nine Months Ended December 31, 2019 (Based on Japanese GAAP)

Release of new Mid-term Business Plan 2022-2022

Summary of Consolidated Financial Results for the Year Ended March 31, 2020 (Based on Japanese GAAP)

Notice of the 98th Annual General Meeting of Shareholders

FACT BOOK 2020

Financial Results Briefing (Fysical Year 2019)

Summary of Consolidated Financial Results for the Three Months Ended June 30, 2020 (Based on Japanese GAAP)

Financial Results Supplementary Material For the Three Months Ended June 30, 2020

Summary of Consolidated Financial Results for the Six Months Ended September 30, 2020 (Based on Japanese GAAP)

Financial Results Supplementary Material For the Six Months Ended September 30, 2020

Financial Results Briefing(Fysical Year 2021)

Toyo Construction puts safe works using dynamic response analysis of floating body into practical application.

TOYO CONSTRUCTION CO., LTD. (Kyoji Takezawa, Representative Director, President) has developed a system for safe works by using numerical simulation technique for dynamic response of floating body at offshore works, and has put the system into practical application.

For numerical analysis of the degree of dynamic response of floating body, the Three-dimensional coupled fluid-structure-sediment-seabed model (FS3M) developed by Nagoya University (Norimi Mizutani, Professor and Tomoaki Nakamura, Associate professor) is utilized.

This system models a towed caisson or crane ship as a floating body and numerically simulates dynamic response caused by ocean wave, which will enable to quantitatively grasp the extent to which the caisson or crane ship will react attacked by the ocean wave and consequently enable to set up countermeasures for mitigating the impact and define a criterion for suspending work against expected ocean waves.

The Company has implemented safe construction practices by utilizing this system in construction works of breakwater, including a construction work of breakwater for Kuji Port district (North bank) in Iwate prefecture.

We will, in the future, improve skills for safe and efficient construction technologies and contribute to safe & secure and sustainable society with support of decision-making process for appropriateness of construction by integrating the database built through advanced numerical simulation and the empirical value obtained through various construction achievements.

Commencement of technology development for CO2 fixation and materialization of coal ash from CO2 absorption equipment or disposal site ~ “Technology development of elements for CO2 fixation & effective utilization by coal ash and biomass ash” is adopted as a NEDO’s R&D commissioned project ~

Central Research Institute of Electric Power Industry (Chiyoda-ku, Tokyo, Masanori Matsuura, President, hereinafter “CRIEPI”), Mitsubishi Power, Ltd. (Yokohama city, Kanagawa pref., Ken Kawai, President and CEO, hereinafter “Mitsubishi Power”), TOYO CONSTRUCTION CO., LTD. (Chiyoda-ku, Tokyo, Kyoji Takezawa, Representative Director, President, hereinafter “Toyo Construction”), and Japan Coal Energy Center (Minato-ku, Tokyo, Masayoshi Kitamura, Chairperson, hereinafter “JCOAL”) will commence following technology development for coal ash, biomass ash and the like.

① Development of CO2 fixation system by CO2 absorption equipment

② Development of CO2 fixation system utilizing disposal site

③ Development of basic manufacturing technology for materialization of carbonated ash

This was applied for the commissioned project “Technology development of carbon recycling & next-generation thermal power generation / Technology promotion project of next-generation thermal power generation / Technology development of common base for carbon recycling technology”, and has been adopted. The term of the project is two years from FY 2020 to FY 2021.

Of various waste in Japan, many of combustion ash such as coal ash and biomass ash contain alkaline metal ion such as calcium or magnesium. Alkaline component of these reacts with CO2 and forms stable carbonate.

In this R&D, we think of “technology to carbonate CO2” as one of the promising technologies for carbon recycling, and by implementing following contents in order to promote technology development of common base for establishment of element technology, we will develop technology for development of CO2 fixation system using combustion ash and for utilization of carbonated combustion ash.

① Development of CO2 fixation system by CO2 absorption equipment (Figure 1) (Assigned to Mitsubishi Power)

Conducting R&D for the design specification generation of CO2 absorption equipment according to property of each ash, which varies by type of fuel

・Evaluation of CO2 fixation ability and reaction rate regarding coal ash and biomass ash from different type of fuel

・Examination of reaction process

・Examination regarding dynamics of chemical substance such as heavy metal

② Development of CO2 fixation system utilizing disposal site (Figure 2) (Assigned to CRIEPI and Toyo Construction)

Examination of CO2 injection method recognizing disposal site as CO2 fixation reactor, and conducting R&D regarding water quality prediction & disposal of the leachate from disposal site for early stabilization of disposal site with CO2 fixation

・Examination of CO2 concentration & pressure suitable for carbonatization assuming CO2 fixation in disposal site

・Elucidation of mechanism of elution of heavy metal due to carbonatization

・Establishment of method to process retained water (water contacted by landfill object)

③ Development of basic manufacturing technology for materialization of carbonated ash (Figure 3) (Assigned to JCOAL)

Conducting R&D for development of basic technology regarding manufacturing materials using carbonated ash

・Research of applicable usage of carbonated ash

・Examination of solidification method according to usage application and examination of stability

Each company will recognize CO2 expelled from power generation and the like as a resource, and through technology development utilizing industrial by-product, will contribute to realization of a low carbon & sound material-cycle society and achievement of SDGs.

Figure 1: Development elements and conceptual scheme of “① Development of CO2 fixation system by CO2 absorption equipment”

Figure 2: Development elements and conceptual scheme of “Development of CO2 fixation system utilizing disposal site”

Figure 3: Development elements and conceptual scheme of “Materialization of carbonated ash”

Commencement of NEDO “Research & Study of Technological Development for Lowering Construction Cost of Floating Offshore Wind Power Generation”

MODEC, Inc. (Chuo-ku, Tokyo, Yuji Kozai, President & Chief Executive Officer, hereinafter “MODEC”), TOYO CONSTRUCTION CO., LTD. (Chiyoda-ku, Tokyo, Kyoji Takezawa, Representative Director, President, hereinafter “Toyo Construction”), and Furukawa Electric Co., Ltd. (Chiyoda-ku, Tokyo, Keiichi Kobayashi, Representative Director, President, hereinafter “Furukawa Electric”) jointly applied for a publicly offered project “Research & study of technological development for lowering construction cost of floating offshore wind power generation” related with “Demonstration research of next-generation floating offshore wind power generation system (Technological development for lowering construction cost of floating offshore wind power generation)” by New Energy and Industrial Technology Development Organization (NEDO), and the application has been adopted. We are delighted to announce that as of today, October 30, each of the three companies entered into a business trust agreement with NEDO.

For realization of decarbonized society, offshore wind power generation, which has been introduced mainly in Europe, is shifting its site location from at coastal area to more windy offshore area to raise energy efficiency. Also, in Japan with large territorial sea, floating offshore wind power generation, in addition to traditional bottom-mounted offshore wind power generation, is attracting attention.

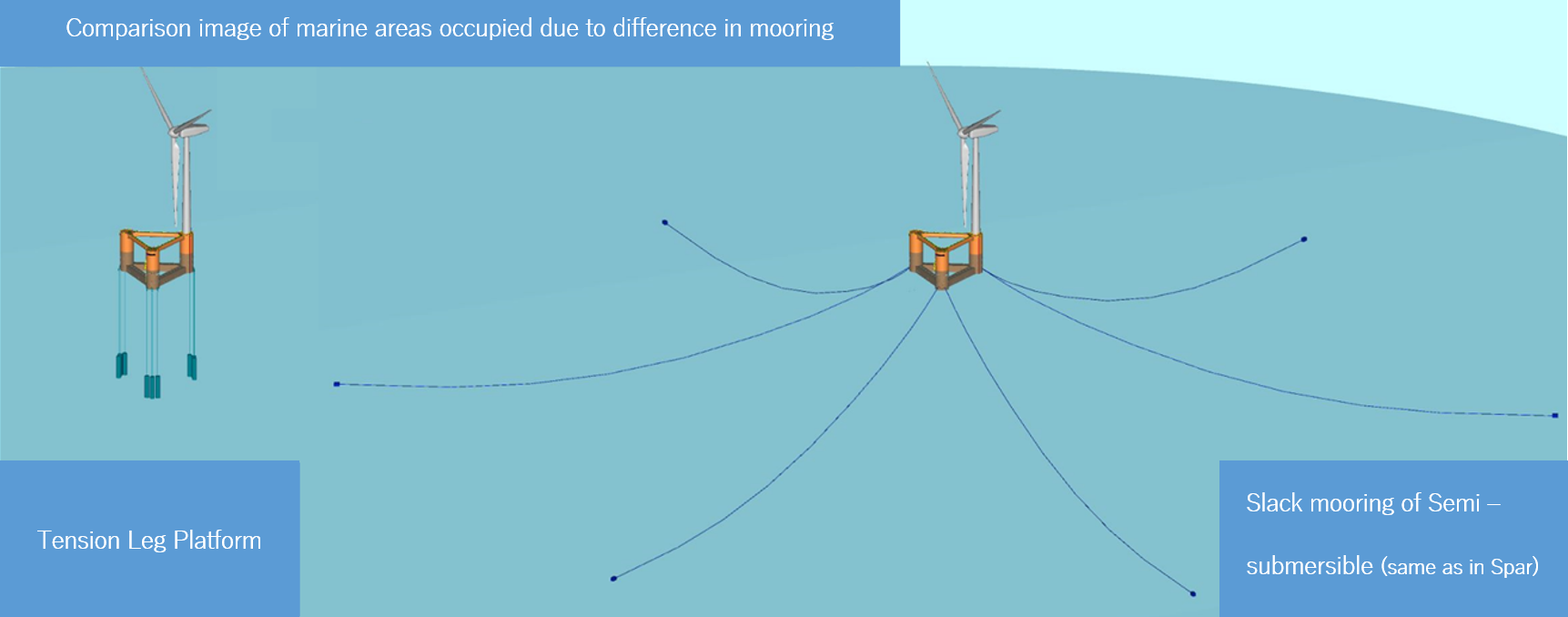

In this Research & Study, for mooring method of floating body, instead of a slack mooring method which has been demonstrated domestically & abroad as a mooring method for floating body of offshore wind power generation, a floating body mooring system by Tension Leg Platform (hereinafter “TLP”) is adopted to reduce costs (see Figure 1 and 2). In the Research & Study, we will ensure structure reliability required as a floating body mounting 10MW-over-class large windmill to be assumed in real business operation by utilizing excellent dynamic response characteristic of floating body on TLP, and also will develop low-cost next-generation floating body system and underwater cable system by durability enhancement of wind power generation equipment and underwater power transmission system due to little dynamic response. Also, compared with the slack mooring method, it enables drastic reduction of space occupied in marine area by mooring line, therefore, it will demonstrate excellent social receptivity by limiting influence on fishery and ship operation.

The term of this project is two years until March 2022. MODEC will be in charge of floating & mooring system, Toyo Construction will be in charge of design of mooring foundation and offshore works, and Furukawa Electric will be in charge of power transmission system, and then technology development and cost reduction will be evaluated.

Toyo Construction is also working on demonstration experiment on technology of bottom-mounted offshore wind power generation facility foundation (suction bucket foundation) with subsidy by NEDO, and will establish construction method of offshore wind power generation facility foundation for both of bottom-mounted and floating, and will contribute to the spread of offshore wind power generation in the future in Japan.

[Figure 1] Image courtesy: MODEC, Inc.

[Figure 2] Image courtesy: MODEC, Inc.

CELBIC (Environmentally Friendly BF Concrete) A Group of Thirteen General Contractors Obtained a Certificate of Technical Performance for Construction Materials to Promote its General Use

The CELBIC Study Group (consisting of thirteen companies: Haseko Corporation (organizer), Asunaro Aoki Construction Co., Ltd., Asanuma Corporation, Hazama Ando Corporation, Okumura Corporation, Kumagai Gumi Co., Ltd., Konoike Construction Co., Ltd., Penta-Ocean Construction Co., Ltd., The Zenitaka Corporation, Tekken Corporation, Tokyu Construction Co., Ltd., Toyo Construction Co., Ltd, and Yahagi Construction Co., Ltd.) has obtained a Certificate of Technical Performance for Construction Materials (GBRC Material Certification No. 20-02) from General Building Research Corporation of Japan as of October 5, 2020 for “Environmentally Friendly BF Concrete (CELBIC)”, a concrete made of ordinary Portland cement mixed with 10-70% ground granulated blast-furnace slag.

CELBIC, an acronym for “Consideration for Environmental Load using Blast Furnace Slag In Concrete”, is an environmentally friendly concrete that reduces carbon dioxide emissions from concrete materials by approximately 9 to 63% while ensuring the quality of concrete required for construction of concrete structures, aiming to contribute to establishing a sound material-cycle society and solving global environmental issues. CELBIC can be manufactured and shipped as a concrete conforming to JIS A 5308 (ready-mixed concrete) and will be constructed under the responsibility of the thirteen companies participating in the CELBIC Study Group.

In the future, we will apply this environmentally friendly CELBIC effectively and efficiently to buildings and other reinforced concrete structures in order to encourage the widespread use.

Certificate of Technical Performance for Construction Materials for CELBIC

Mock-up specimen fabricated in the development experiment

■Environmental considerations

Ground granulated blast-furnace slag is made by pulverizing by-product slag produced during pig iron making in the blast furnaces of ironworks and has hydraulic properties.

Since the amount of carbon dioxide emitted during the manufacture of ground granulated blast-furnace slag is less than 1/20 than that of ordinary Portland cement, effective use of this granules is desired to reduce the environmental impact.

Ground granulated blast-furnace slag is a concrete material used as a substitute for cement as one of the admixture materials under JIS A 5308 (ready-mixed concrete). In general, it is distributed as blast furnace slag cement class B, which is pre-mixed with Portland cement in a prescribed amount (at 40-45%) at a cement plant.

■Features

CELBIC is produced in a ready-mixed concrete plant using ordinary Portland cement and ground granulated blast-furnace slag as the concrete material, and according to the application parts or components of the building and the specified performance, 10% to 70% of the cement is replaced with ground granulated blast-furnace slag.

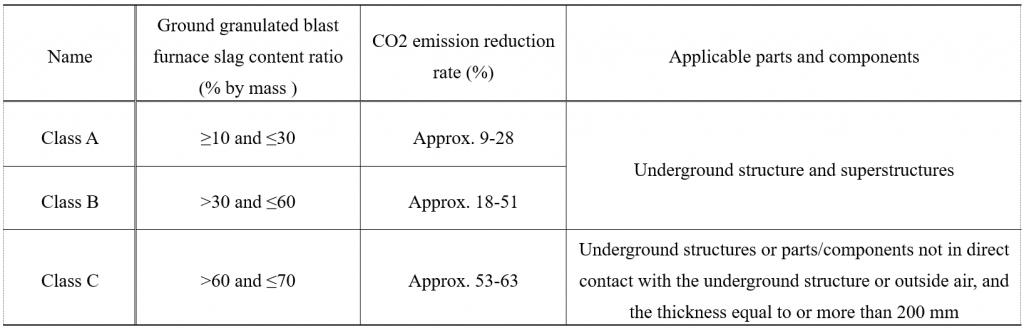

CELBIC is classified into three classes according to the amount of ground granulated blast-furnace slag: Class A, Class B and Class C.

Of these, Class A has performance similar to concrete made of ordinary Portland cement, while Class B has performance similar to that of blast furnace slag cement Class B. Class C reduces carbon dioxide emissions by more than 60%, although the application at sites are limited. In addition, since these three types of CELBICs use the same ground granulated blast-furnace slag, the burden of material management at the ready-mixed concrete plants is alleviated, and generic application for building structures by taking advantage of the distinctive features of each type is expected.

Names of CELBIC types, ground granulated blast furnace slag content ratio, Co2 reduction rate, and applicable parts and components

■Development experiment

In the development experiment, we confirmed the strength development and durability of concrete under various conditions using several kinds of ground granulated blast furnace slag mainly distributed in Japan, and verified the basic performance of the concrete according to the content ratio of ground granulated blast-furnace slag.

Based on the results, we determined the selection of the plant and the method of concrete mix design, followed by the construction verification assuming the manufacture of CELBIC and actual parts and components at the actual ready-mixed concrete plant, and prepared the mix design & construction manual for CELBIC.

Developing fishing ground construction system using quasi-zenith satellite “Michibiki”

TOYO CONSTRUCTION CO., LTD. (Kyoji Takezawa, Representative Director, President) has developed “Fishing ground construction system – QZSS”, which utilizes a quasi-zenith satellite “Michibiki”, by expanding traditional fishing ground construction systems.

This system enables to visualize status of offshore construction such as construction of upwelling fishing grounds (mound fish bank) or protective reefs, and in addition to traditional GNSS positioning systems centered on GPS, has realized high-accuracy of offshore construction by utilizing a quasi-zenith satellite “Michibiki”.

Fishing ground construction works are usually implemented through a cycle of “injection plan”, “ocean research (tidal current)”, “construction” and “survey”; however, water is deep in the marine area for fishing grounds and tidal stream is fast, therefore, it is required for a work to inject materials accurately.

In offshore construction, because adjusted data of RTK positioning method (accuracy approx. 2cm~10cm) is not reachable, a differential positioning method (accuracy approx. 50cm~100cm) is used; however, now, a quasi-zenith satellite “Michibiki” is utilized for more accurate positioning calculation. “Michibiki” is a Japanese satellite positioning system which began operation from November in 2018, and Centi-meter Level Augmentation Service (CLAS) is provided. The Company developed a construction control system whose accuracy improved from ±50cm to ±10cm by using this technology, and adopted the system for the first time for construction of offshore structure, which achieved a good performance.

Installation status of GNSS positioning system

Construction status (left) and screen of fishing ground construction system (right)

At offshore construction sites, construction status may vary due to nautical conditions. In the future, we will realize high-quality fishing ground construction by coordinating wave measurement technology and rolling alleviation technology with this system and contribute to improvement in safety aspects.