CORPORATE REPORT 2020

Financial Results Supplementary Material For the Ended March 31, 2021

Summary of Consolidated Financial Results for the Year Ended March 31, 2021 (Based on Japanese GAAP)

FACT BOOK 2021

Financial Results Briefing(Fysical Year 2021)

Notice of the 99th Annual General Meeting of Shareholders

Notice of Resolutions of the 99th Annual General Meeting of Shareholders

Financial Results Supplementary Material For the Three Months Ended June 30, 2021

Summary of Consolidated Financial Results for the Three Months Ended June 30, 2021 (Based on Japanese GAAP)

Award of Construction Contract for Pasig-Marikina River Channel Improvement Project (Phase IV) in the Philippines

| Package 2 | Package 3 | ||

| Work Period | 1,460 days from start of construction | Work Period | 1,460 days from start of construction |

| Contractor | Toyo Construction Co., Ltd. | Contractor | JV composed of Toyo Construction and Shimizu Corporation |

| Outline of construction | Section for improvement: 2.6 km

Revetment by hat-shaped steel sheet pileTotal extension: 105,000 m

Weight: approx.. 31,000 tons

Concrete work: 25,000 m³

Dredging work: 613,000 m³ |

Outline of construction | Section for improvement: 4.05 km

Revetment by hat-shaped steel sheet pile

Total extension: 144,000 m

Weight: approx.. 36,000 tons

Concrete work: 49,000 m³

Dredging work: 905,000 m³ |

Conduct of a verification test of construction technology for the suction bucket foundation in a real sea area

Toyo Construction Co., Ltd. (Chiyoda-ku, Tokyo Metropolis, President and Representative Director: Kyoji Takezawa, hereinafter “Toyo Construction”) and Hitachi Zosen Corporation (Osaka City, Osaka prefecture, Sadao Mino: Representative Director President & COO, hereinafter “Hitachi Zosen”) have conducted a verification test of construction technology for the suction bucket foundation, aiming at application to bottom-mounted offshore wind power generation facilities, in a real sea area this summer. This project is implemented with subsidy from NEDO (New Energy and Industrial Technology Development Organization) for the “Low-Cost Construction Technology Development for Offshore Wind Power Generation (Verification of Construction Technology)” of Research and Development of Wind Power Generation Technologies (Research and Development of Offshore Wind Power Generation Technologies).

In this development, Toyo Construction is in charge of construction and Hitachi Zosen is in charge of design & manufacturing; in the test in the real sea area, using a quarter scale model, Toyo Construction conducted an experiment on the construction and Hitachi Zosen on the structure.

Regarding the workability of the suction bucket foundation, we conducted verification including removal and confirmed that the impact of vibration, noise, and pollution during the construction on the surrounding environment was very low.

The two companies will, through technology verification, aim for practical use of the suction bucket foundation around 2026.

We will contribute to the realization of a low carbon & sound material-cycle society by developing technologies for spread of clean energy.

Status of Verification Test

Suction bucket used for the test

Quiet enough to maintain visual recognition of fish at the time of penetration

Summary of Consolidated Financial Results for the Six Months Ended September 30, 2021 (Based on Japanese GAAP)

CORPORATE REPORT 2021

Financial Results Briefing(Fysical Year 2022)

Toyo Provides Emergency Assistance for Philippines after Typhoon No. 22

The extremely powerful typhoon No. 22 (local name: Odette), which devastated the south-central Philippines from 16th to 18th of December last year, caused considerable damage to the country.

The number of dead rose to 405 as of December 31, 530,000 houses were destroyed, and approximately 500,000 people have had to take refuge. Also, in the disaster areas, transportation and telecommunications are disrupted, which has made it difficult to secure food and water.

The Company, as part of support for affected areas, especially for disaster victims in Cebu Island and Bohol Island where particularly severely damaged, provided emergency shipping by loading emergency relief goods such as food, water and fuel onto two of our own vessels from the nation’s capital, Manila around the year-end.

The Company and CCT, our overseas subsidiary, have participated in various projects in the Philippines for about 50 years, which has strengthened our ties with the country. We would like to express our heartfelt sympathies to all those affected by the disaster, and sincerely look toward the earliest recovery of the affected areas.

Barge loaded with emergency relief goods

Unloading at Bohol Island

The water route of support vessel

Unloading at Cebu Island

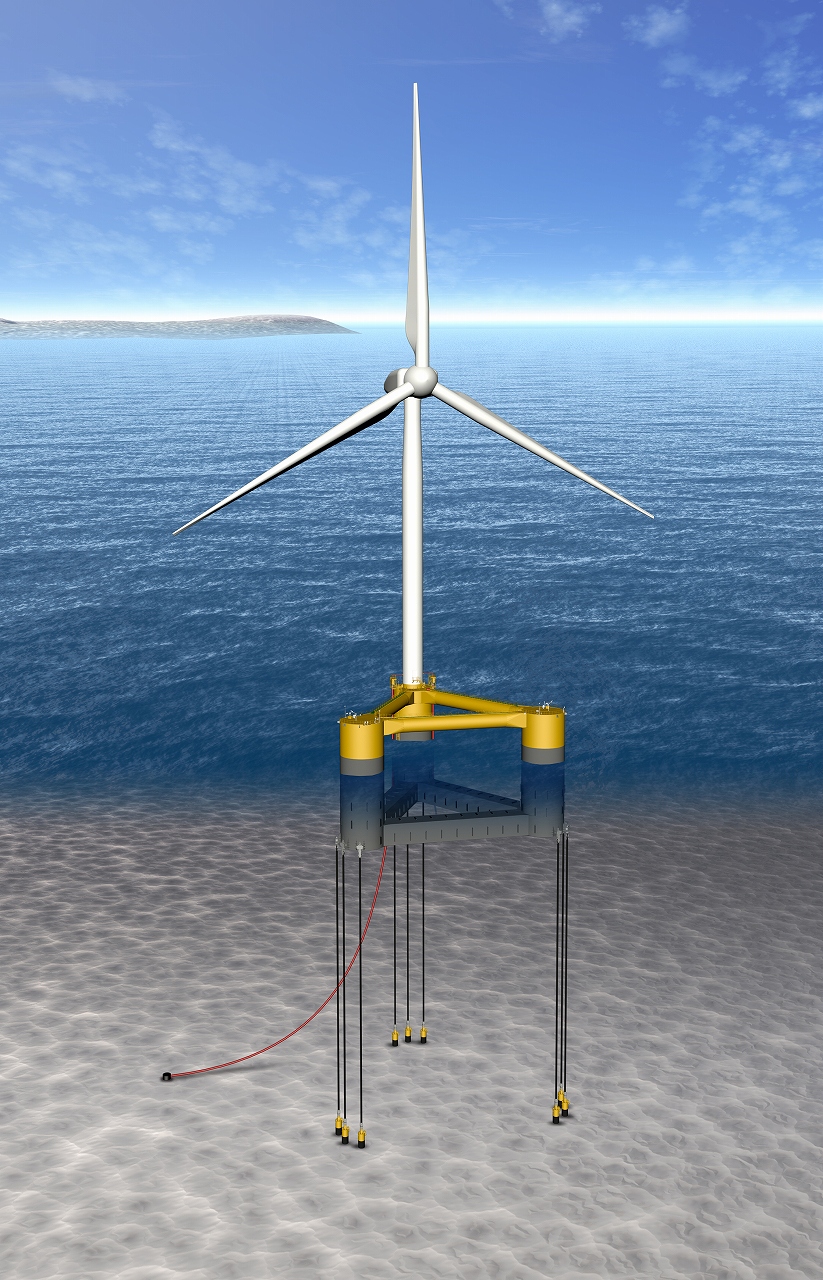

Project to Develop Cost-Reducing Technology for TLP Floating Offshore Wind Turbines

Tokyo – 21 January 2022 – Toyo Construction Co., Ltd. (“Toyo Construction”), together with MODEC, Inc. (“MODEC”), Furukawa Electric Industry Co., Ltd. (“Furukawa Electric”), and JERA Co., Inc. (“JERA”), has received, on 21 January, notice of acceptance of their joint grant application, under the Green Innovation Fund program of the New Energy and Industrial Technology Development Organization (“NEDO”), to conduct a project to develop cost-reducing technology for tension leg platform (“TLP”) floating offshore wind turbines (the “Project”).

To achieve carbon neutrality by 2050, the Japanese government has set a goal of increasing offshore wind power generation capacity, including floating offshore wind, to 30–45 GW by 2040. Because Japan has limited shallow-water sites where the bottom-fixed offshore wind turbines now being developed around the world can be installed, there is a strong domestic demand for practical floating offshore wind turbines that can be installed in deep water further from shore.

TLP systems are expected to reduce the cost of power generation because the high stability of tension mooring to a seafloor foundation enables installation of large 15 MW-class wind turbines, which have the potential to become mainstream in the future, on compact floating platforms. In addition, TLP mooring lines are expected to be more socially acceptable than other mooring systems because they can reduce the space occupied under the sea by 1/1,000 approximately and have less impact on existing businesses such as the fishing industry and ship operations.

The Project aims to establish component technologies for TLP floating and mooring systems and subsea power transmission systems with the aim of commercializing floating wind farms in the early 2030s.

The four companies will jointly conduct component technology development under contract from NEDO for two years beginning in April 2022. JERA will conduct surveys and measurement of the planned verification site, design power generation facilities, and establish environmental parameters. In addition to conducting simulations and demonstrations of component technologies previously studied by each company—floating and mooring systems by MODEC, mooring foundations by Toyo Construction, and power transmission systems by Furukawa Electric—a basic plan for a 15 MW-class power generation demonstration facility will be drawn up based on design and environmental parameters provided by JERA. The four companies will also begin considering supply chains for mass production and cost reduction with the aim of realizing commercial projects following the power generation demonstration.

Toyo Construction raises the offshore-wind-power related business as a “growth driver” and is promoting the business to make it our future core business. Particularly, we put priority and focus on developing technologies for lowering costs related to the offshore wind power generation business. In this business, we will contribute to the spread of offshore wind power generation in the future in Japan with maximized utilization of our rich track record in the design and construction of offshore structure.

Conceptual drawing of TLP (Tension Leg Platform)[Source: MODEC]

Summary of Consolidated Financial Results for the Nine Months Ended December 31, 2021 (Based on Japanese GAAP)

Toyo Construction and MOL Sign MoU on Collaboration in Offshore Wind Power Generation Related Work Vessel

TOKYO— Toyo Construction Co., Ltd. (President: Kyoji Takezawa; Headquarters: Chiyoda-ku, Tokyo) and Mitsui O.S.K. Lines, Ltd. (MOL; President & CEO: Takeshi Hashimoto; Headquarters: Minato-ku, Tokyo) today announced that the companies signed a Memorandum of Understanding (MoU) on evaluating potential collaboration in offshore wind power plant construction, with the aim of commercializing vessels for offshore construction related to offshore wind power projects in Japan and overseas.

The companies aim to open up new business opportunities for work vessels which will be required for offshore wind power projects, based on the demand for vessels related to offshore wind power business in Japan and overseas.

The companies will meet demand for various types of work vessels in offshore wind power projects in Japan and overseas by combining MOL’s abundant track record in construction, ownership, and operation of vessels with Toyo Construction’s abundant knowledge of marine engineering and technological development in offshore wind power, and broadly contribute to value chains in the offshore wind power business, which is positioned as a key renewable energy source in the future.

Establishment of Toyo Construction (Hanshin Harbor Construction Co., Ltd. at the time) was due largely to the idea of Kamesaburo Yamashita, President of Yamashita Kisen K.K., one of MOL’s corporate predecessors. Yamashita Kisen became the largest shareholder, and President Yamashita oversaw the first generation of the president of Toyo Construction. Utilizing this relationship, established through the long histories of both companies, MOL and Toyo Construction will build a firmer partnership through offshore wind power business.

About Toyo Construction

Since its founding in 1929, Toyo Construction has become one of Japan’s top-class marine contractors, which has an extensive record of success in marine engineering using work vessels in Japan and overseas. In addition, it sets offshore wind power as a growth driver of its business, focusing on technology development and capital investment in fixed-bottom as well as floating-type wind turbines. For details, please

visit: https://www.toyo-const.co.jp/en/

About MOL

MOL was founded in 1884, and its business centers on the ocean shipping industry. Operating a fleet of about 800 vessels, it develops a variety of social infrastructure businesses. MOL is the first company in the ocean shipping industry to set a target of achieving net zero GHG emissions by 2050, and the entire MOL Group is engaged in wind power projects and committed to reducing GHG emissions. For details, please

visit: https://www.mol.co.jp/en/index.html

Scope of collaboration (image)

For further information, please contact:

Toyo Construction Co., Ltd.

Offshore Wind Dept. Civil Construction Div.

TEL: 03-6361-5462

Mitsui O.S.K. Lines, Ltd.

Media Relations Team, Corporate Communication Division

TEL: 03-3587-7015

Establishment of Basic Policy on Sustainability

The Company announces the establishment of the Basic Policy on Sustainability as described below.

Toyo Construction Group’s Basic Policy on Sustainability (Established February 2022)

Toyo Construction Group strives to build better-quality and more-valuable social infrastructure by implementing the ”devotion to customer and public society” as our Corporate Identity and training ourselves in construction technologies to meet social demands as a company engaged in the construction business.

Our Group’s sustainability means our contribution to sustainable social development in compliance with our Code of Conduct based on our Corporate Identity and by deploying fair and reliable business activities with better relationship with the society.

Top management will, in the acknowledgement that realization of this Basic Policy is its own role, not only demonstrate leadership along with this policy, but also give thorough instructions to all persons concerned inside the company. And we will, always perceiving stakeholders’ voice, establish and maintain a workable company structure.

Environment/For global environmental conservation, we:

◆ Commit to reduction of carbon dioxide for realizing a low-carbon society.

◆ Work for reduction & thorough reuse of waste for lowering environmental load.

◆ Work for biodiversity conservation for maintaining a rich natural environment.

Social/For all stakeholders, we:

◆ Aim to earn customer satisfaction and trust through building a good-quality social foundation. Also, in the event of a natural disaster such as a large-scale earthquake, we will get involved in disaster relief efforts in an immediate and organized manner to fulfill our social mission imposed on a construction company.

◆ Create an attractive working environment by respecting human rights, eliminating any and all irrational discrimination, and promoting reform of working practices and improvement of workplace environment.

◆ Secure and develop precious human resources as the basis of our business activity through education and training.

◆ Contribute to revitalization of local communities and realization of an affluent society through our business activities and CSR activities.

Governance/For fair and reliable business activities, we:

◆ Undertake fair and sincere business activities in compliance with laws & regulations and spirit thereof as well as international rules.

◆ Establish an appropriate governance system that contributes to increasing corporate value.

◆ Make efforts to gain a more precise understanding of our business activities by providing corporate information widely to the public.

Announcement of Construction of Cable-laying Vessel

Toyo Construction Co., Ltd. (President and Representative Director: Kyoji Takezawa) are pleased to announce the decision to construct a new vessel for cable laying.

Offshore wind power generation, which is considered an effective means of Japan’s renewable energy business, is expected to begin full-scale implementation in the oceanic region. Various work vessels will be required for construction of offshore wind power generation facilities, and particularly, there will be a very strong demand for self-propelled work vessels that handle the cable laying work, partly because, in addition to the fixed-bottom and floating type, the submarine DC power transmission connecting Honshu and Hokkaido promoted by the government is scheduled. Also, since the introduction of floating offshore wind power generation is expected to progress, it is expected that there will be increasing demand for suitable offshore work vessels.

For these reasons, we have decided to construct the nation’s largest self-propelled cable-laying vessel to meet these demands.

We will construct the vessel taking into account the construction of floating offshore wind power generation facilities, and by utilizing the cable-laying vessel in various fields, we will contribute to the spread of offshore wind power generation.

Image of the cable-laying vessel

【Intended use】

● Laying a submarine cable between an offshore wind power generation facility and an onshore substation

※ Overview of the submarine cable laying work

Laying a power cable loaded on the cable laying vessel along a planned route; connecting turbines to each other and to the onshore terminus.

● Various offshore works such as foundation pile works for fixed-bottom and floating type

【Features】

● 120m long and 27m wide; large deck area of approx. 2,500m2 which enables the arrangement of equipment necessary for cable-laying and offshore construction.

● Self-propelled vessel equipped with a propulsion device enabling self-navigation in the oceanic region.

● Equipped with a dynamic positioning system equivalent to the DPS Class-2* required for offshore wind power in Europe.

● Equipped with accommodation facilities for a large number of crew members and passengers, enabling long-term offshore work.

● Mounted with a 250t crane with active heave compensation that can handle large water depths.

DPS Class-2*: A redundant system that does not lose positioning capabilities even if the main equipment fails.

【Schedule】FY 2022: Design, FY 2023: Commencement of construction, FY 2025: Completion & Delivery